USAGE INSTRUCTIONS

- Drive the screw into the wood material, perpendicular to its surface.

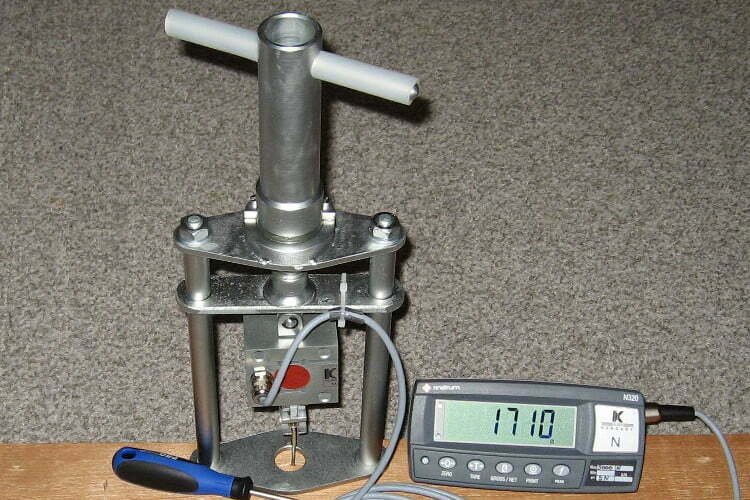

- Connect the cable of the force transducer to the display unit R320.

- Switch on the unit by pressing the “ON” button for 3 seconds.

- Select the Peak hold function.

- Start the screw withdrawal process by placing the mechanics over the screw. Catch the screw head by the fork of the force transducer.

- Slowly turn the handle clockwise until the screw is removed. The speed of the withdrawal should be approximately 0.5 mm/s.

- Record the maximal force value and press the “Max” button before the next test to reset the display.

PACKAGE CONTENTS

- Screw withdrawal mechanics with force transducer

- Display unit, R320

- Screws and screwdriver

- Rechargeable battery and charger

- Aluminium carrying box

- 10 special screws

- User manual

TECHNICAL SPECIFICATIONS

Force transducer capacity 5 kN (survives 10kN)

Temperature sensitivity less than 0.005%/Ko

Hysteresis error less than 0.05%

Repetition error less than 0.03%

Operating temperature -10 °C to +40 °C

Resistance 350 Ω

Material steel

Manufacturer Kaliber MM Kft., Budapest, Hungary

Force meter resolution 5 N

Display unit operation temperature +10 °C to +40 °C

Battery 4 pieces of AA size 1.5 V battery